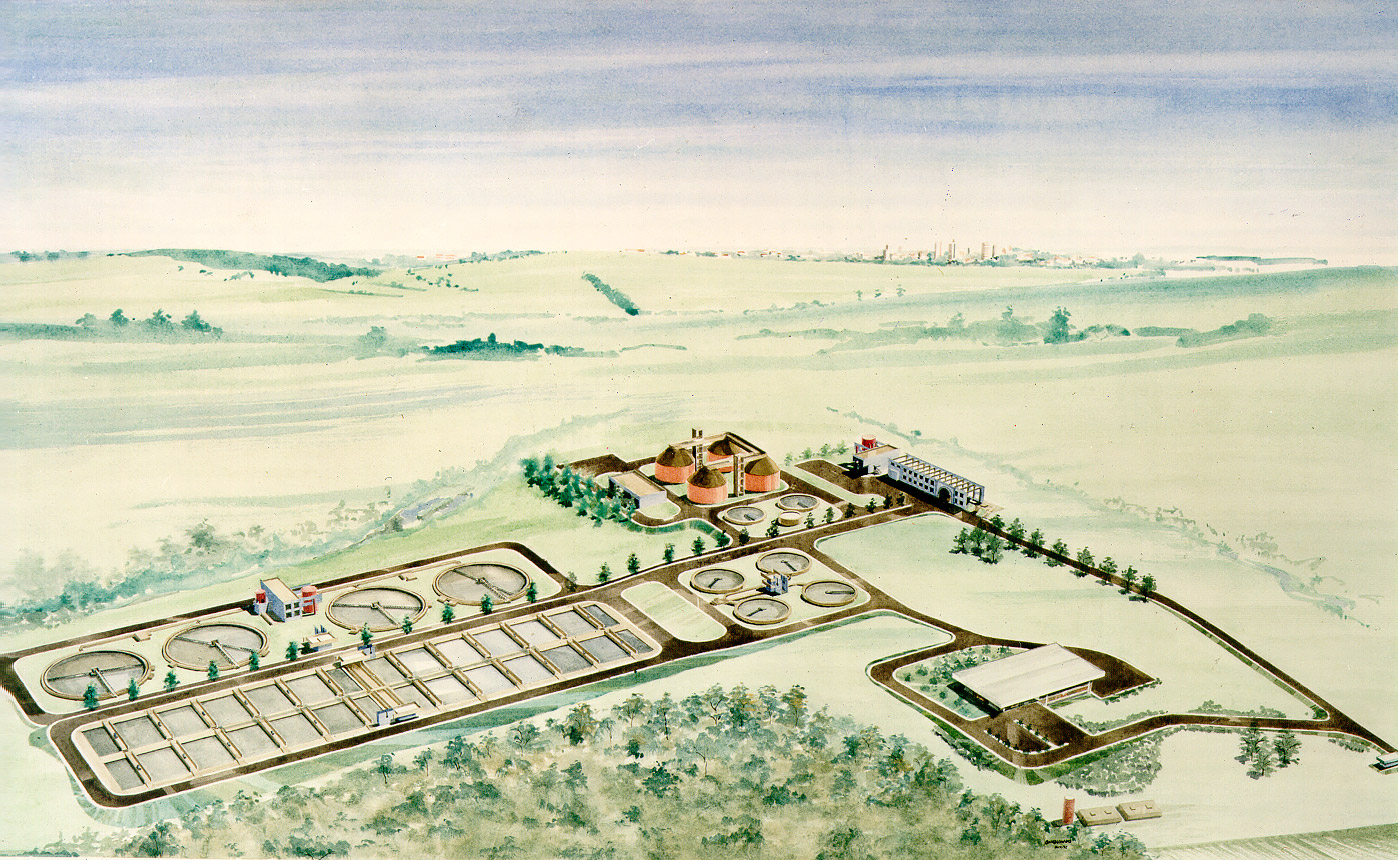

SANITARY WASTEWATER SYSTEM OF FRANCA/SP | SABESP

DETAILED DESIGN AND TECHNICAL FOLLOW-UP OF THE WORKS

SABESP – Companhia de Saneamento Básico do Estado de São Paulo

Jul/1991 to Sep/1993

SETEC developed the detailed design and conducted a technical follow-up for setting up the works related to expansion and improvement of the Sanitary Wastewater System of Franca. This also included a detailed design of the Franca Wastewater Treatment Plant (WWTP), in the State of São Paulo, and is being considered as one of SABESP’s benchmarks. The detailed design comprised the WWTP itself, six pumping stations, 34.8 km of linear works, including 6.5 km of collectors, 3.5 km of emissaries, 6.4 km of drainage lines and 18.5 km of interceptors.. The Treatment Plant was designed to attend 269,752 inhabitants in the first stage (1998, with an average daily flow of 735.2 l/s) and 410,147 inhabitants at the end of the plan (2008, with an average daily flow of 1051 l/s), which altogether comprised the following operations and processes:

- Liquid phase, includes straining, sand removal system, pumping station for raw wastewater, primary sedimentation, conventional activated sludge system;

- Solid phase, includes fine straining for primary sludge; tank for mixing the sludge; sludge thickening by gravity; pumping station for thick sludge to feed anaerobic sludge digesters; anaerobic sludge digestion system; pumping system with flow control for feeding press filter conveyor belts; sludge drying system through conveyor press filters (belt-press); water system for utilities; Electric system capable of receiving electric energy with primary voltage of 13.8kV, with neutral, 3-phase, 60HZ, including substations and motor control centers (CCMs).

Supervisory and control system for the station’s automation.

WWTP

Type- Activared sludge

Final output – 1,051 l/s

269,752 People Attended (1998)

410,147 People Attended (2008)

Pumping stations – 6 Units

Linear works – 34.9 km

Ø 150 mm to Ø 300 mm

DETAILED DESIGN

- Elaboration of a complete detailed design, including: hydraulic/mechanical; foundations and structures; electric installations, instruments and buildings/facilities; architecture and landscaping; pumping stations and wastewater and sludge treatment stations;

- Design of the supervision and control systems.

TECHNICAL FOLLOW-UP OF THE WORKS

- Technical advisory for following-up the works;

- Coordination and management of the interfaces between design/works/equipment;

- Elaboration of an Operating Manual for the Process.